Beijing Melody provides you with first-class violin, viola, bass and cello. In Beijing Melody, every process is purely handmade.

Step 1

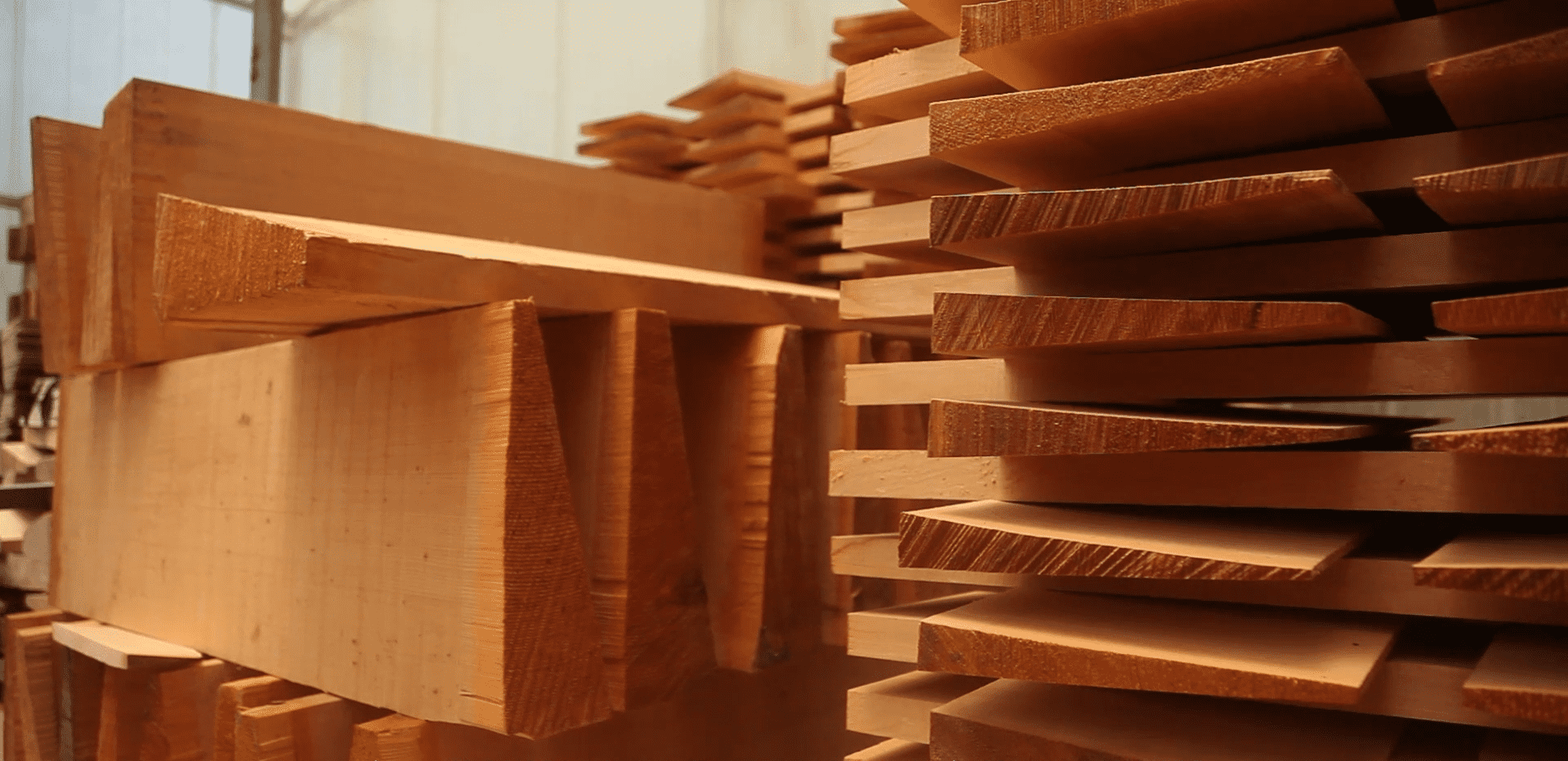

Select materials. Good wood may not make a good violin, but bad wood definitely cannot make a good one, so the selection of materials is the first and most crucial step.

When selecting materials, we must use naturally dried wood with a long time of age, and the wood should be uniform, so as to ensure the sound quality of the instrument is superior.

In this process, we carefully select high-quality wood, using those with 3-20 years of natural drying to make panels and backboards.

Step 2

Glue the cut boards together. The adhesive we use is refined from the skin of animals. This process should be conducted in the high temperature and dry environment. Be careful to well control the amount of adhesive and apply it evenly.

Step 3

Cut and polish the assembled template into the approximate shape of the violin, and then scrape it bit by bit until the front and back plates of the violin are formed. Of course, the size and thickness must be exquisite. We must scrape according to the standard thickness.

Step 4

The sound hole is carved into the scraped board and the sound beam is installed. The sound hole is more demanding in appearance and has a greater impact on the sound production of the instrument.

The sound beam is important for the sound quality of the violin, especially in the bass part, mainly because the beam can drive the vibration of the top, which affects the sound quality.

Step 5

The finished panel, backplane and side plate are bonded and fixed with pigskin glue to form the violin box.

This is a relatively simple process for making a violin, and it does not affect the sound quality much, but if not done properly, it can cause the violin to fracture later.

Post time: Oct-27-2022